Propulsion

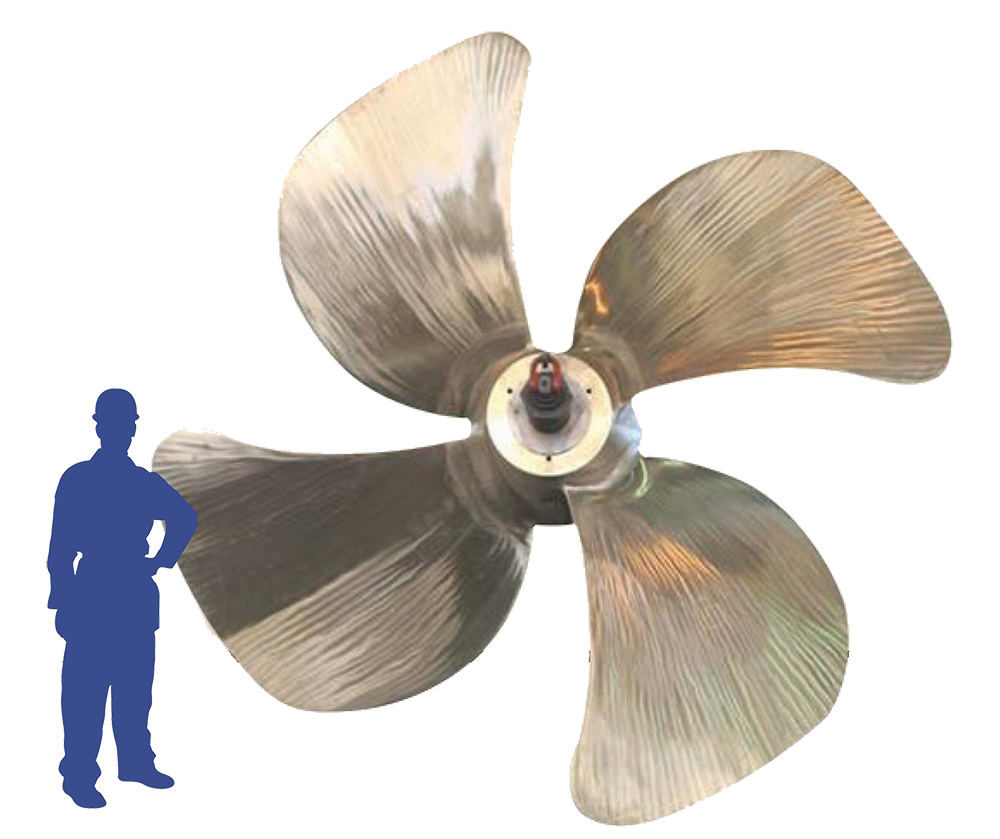

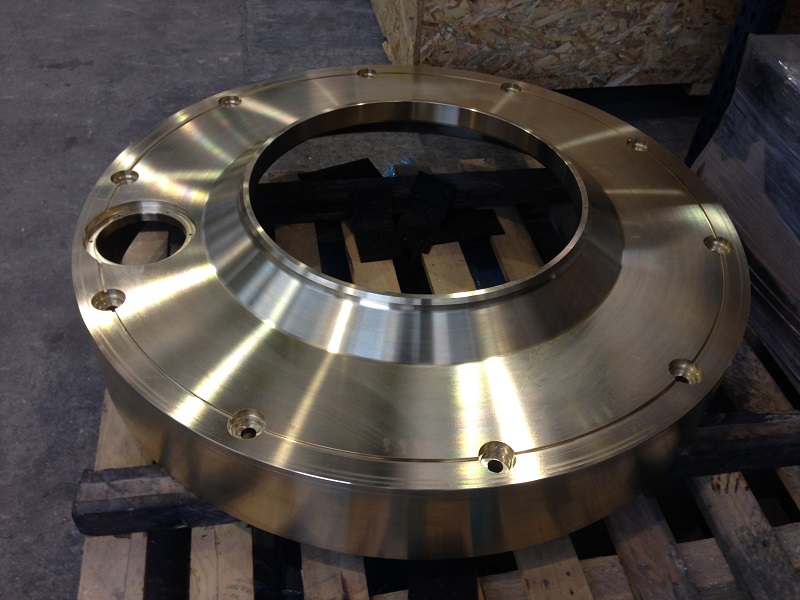

Aluminium bronze is widely used in all ship propulsion applications in the various components mounted on a shaft line which can include : FPP but also CPP propellers (assembly of hubs, blades and caps), sealing rings, POD covers …. Those parts made of NAB alloys, a family of copper based alloys including nickel, aluminium and iron according strict proportions which lead both to very good corrosion resistance to sea water and good mechanical properties. The advantage of aluminium bronze alloys for both sealing and wear parts in contact with sea water is linked to its oxyde protective film preventing the use of anticorrosion paints.

CPP propellers (for controllable pitch propellers) require following components which are in contact with sea water :

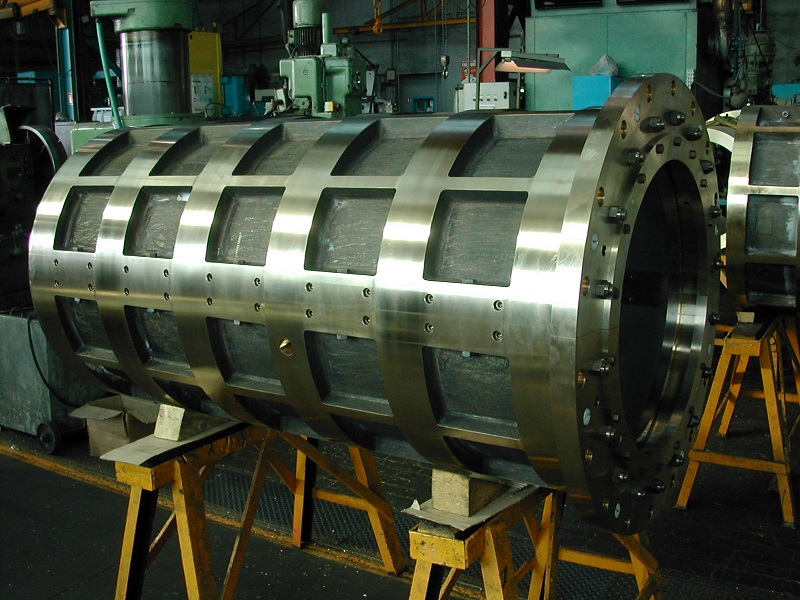

- Hub

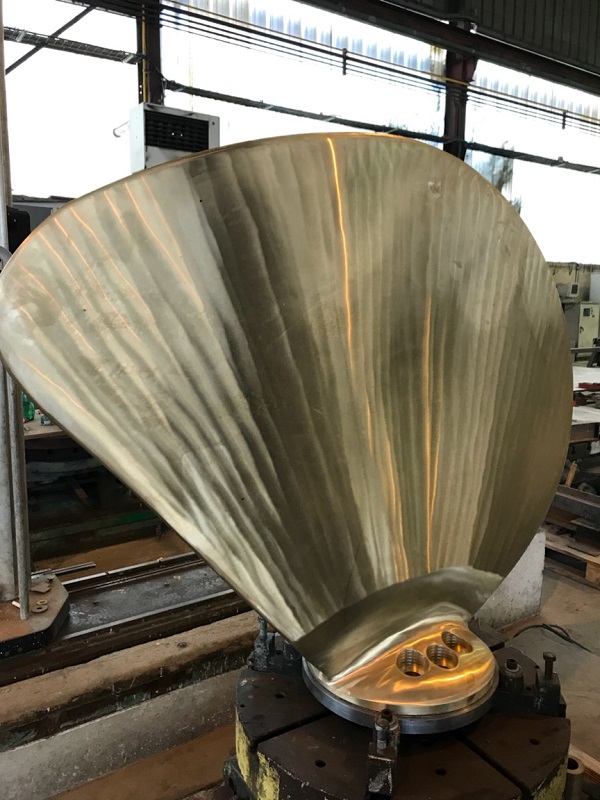

- Blade

- Covers

- Protective shields

Our sand casting capacilities enable us to manufacture those components up to 8To (finished machined weight) for an overall size of 4m X 4m. They can be casted according to any standard either international such as EN 1982, ASTM B148, BS14000 or navy based such as DEF STAN, STF, MILSTD and others. The very strict quality control that CPP propeller components undergo is regularly supervised by third party inspectors from Lloyds, Bureau Véritas, DNVGL, RINA,RMRS for which we hold relevant certifications up to date.

Aluminium bronze sand casted parts are delivered worldwide according to the specified standard, rough or fully machined with its 3.2 certificat according EN 10 204.

Some specific applications require dedicated NAB solutions :

![]() Mine hunters need low magnetic aluminium bronze alloys : example Inoxyda 53AMA

Mine hunters need low magnetic aluminium bronze alloys : example Inoxyda 53AMA

![]() Towed sonars or drones needing higher mechanical characteristics than normal : example Inoxyda 154

Towed sonars or drones needing higher mechanical characteristics than normal : example Inoxyda 154

![]() Electrical motor casings can also be casted in aluminium bronze when they are in contact with sea water : example Inoxyda 3P

Electrical motor casings can also be casted in aluminium bronze when they are in contact with sea water : example Inoxyda 3P

OUR PRODUCTS

CPP NAB alloy Hub

Aluminium Bronze POD Cover

Protective Gard

Fully machined Hubs & Caps

CPP Aluminium Bronze Blade

NAB Alloy Bearing