Pumps & Turbines

The purpose of pumps is to move liquids, which can sometimes be corrosif as for example sea water or certain chemicals, while turbines are mainly used in electricity generation processes. Choosing the correct material is a critical step to ensure long term service of the pump (for industrial process, cooling or firefighting )or turbine (mostly Kaplan) . Aluminium bronze alloys ;, also called NAB alloys or Nickel Aluminium Bronze, are copper based alloys including Nickel, Aluminium and Iron which gives it both very good corrosion resistance and good mechanical properties, in particular regarding cavitation. Copper based alloys of NAB family should be considered at early design stages in comparison to titanium and duplex or super duplex steels as they offer several advantages among which a good machinability .

Aluminium Bronze alloys are available using various casting processes : sand casting, centrifugal casting or continuous casting for smaller fully machined pump components but also using forging when looking very higher mechanical characteristics thus offering opportunities to manufacture various engineered pump components such as :

- Pump casings ( split pump, centrifugal, volute)

- Impellers (closed, open, fish freindly)

- Suction casings or diffusers

- Discharge elbows

- Riser colums

Our in house capacities enable us to cast about any pump components up to roughly 4m X 4m and 8to finished machined weight. Casted aluminium bronze components are available according various international standards ( EN1982, ASTM B148, BS…) or military (Def Stan, Gamm MM11 or MM12, MILSTD) and can be delivered worldwide in as-cast, rough or final machined stage (including pressure testing, balde sharpening, slotting or balancing). On the side of well known standardised NAB alloys, specific aluminium bronze grades such as Inoxyda 3 Cryo have been developped for very low temperatures.

OUR PRODUCTS

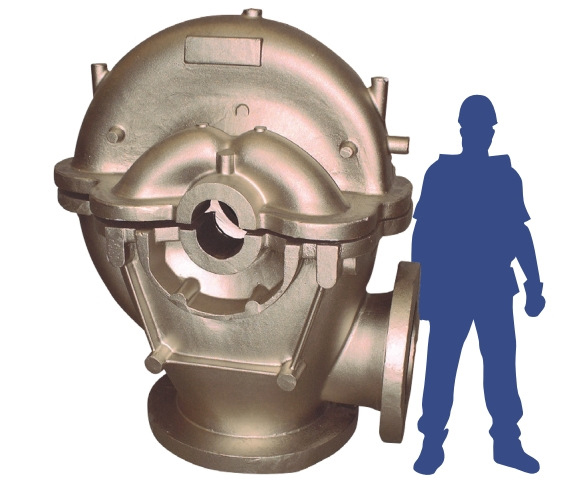

NAB Alloy Pump Casings and Covers

Casted Aluminium Pump Components

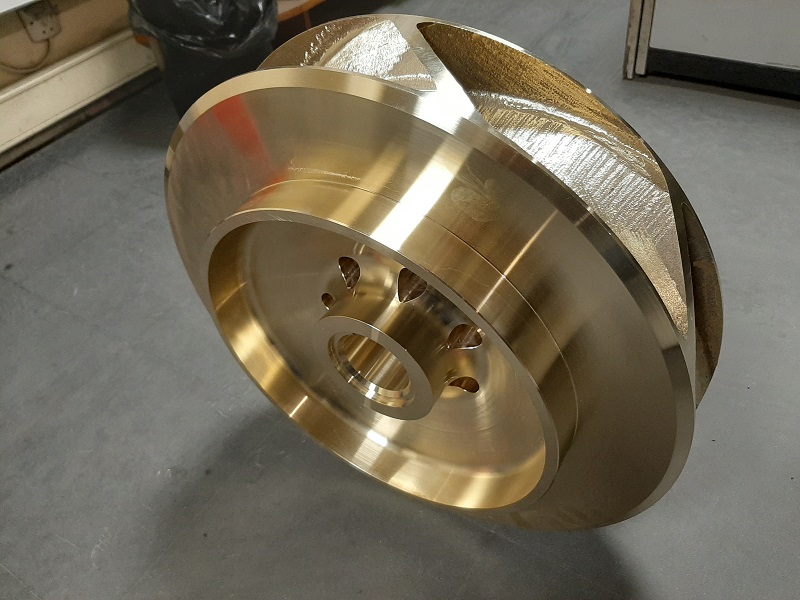

ASTM B148 C95800 Impeller

Nickel Aluminium Bronze Impeller

NAB Casted Discharge Elbow

Lower Pump Casing - NAB

Fully Machined Pump Impeller

NAB Casted Split Pump Casings